The world of dentistry is rapidly evolving, and at the forefront of this transformation is the integration of CAD/CAM technology. This digital revolution is streamlining processes, improving patient experiences, and delivering superior results. A crucial element of this digital workflow is the CAD CAM block, the building block of modern dental restorations. In this post, we’ll explore the significance of CAD/CAM blocks, particularly in the context of same-day crowns and bridges, and highlight the advantages they offer over traditional methods.

From Impression to Restoration: The Traditional vs. Digital Workflow

Traditionally, creating dental restorations like crowns and bridges was a multi-step, time-consuming process. It involved taking physical impressions using messy materials, transferring them to a dental articulator with a facebow, and then sending the impressions to an outside dental lab. At the lab, skilled technicians would meticulously craft the prosthetics, often from metal porcelain, through numerous hand-operated steps. This process relied heavily on the technician’s experience to achieve the correct occlusion and aesthetics. Patients often had to wait weeks, sometimes even months, for their final restoration, enduring temporary solutions in the meantime.

Enter the CAD/CAM digital workflow. This game-changing approach eliminates many of the drawbacks of traditional methods. Instead of physical impressions, digital scans are taken using intraoral scanners. These scans capture highly accurate 3D images of the patient’s mouth, which are then used to design the restoration on a computer using CAD (Computer-Aided Design) software. The design is then sent to a milling machine, which carves the restoration from a solid block of material – the CAD CAM block. This entire process can often be completed in a single dental visit, allowing patients to walk out with their permanent crown or bridge the same day.

The Rise of Zirconia: A Dentist’s and Patient’s Favorite

When it comes to materials for dental restorations, zirconia has emerged as a favorite, especially in the CAD/CAM era. Zirconia is a type of ceramic that offers an exceptional combination of strength, aesthetics, and biocompatibility. It is highly durable, resistant to wear and fracture, and can be fabricated to closely mimic the appearance of natural teeth. This makes it an ideal choice for crowns, bridges, and even full-arch restorations.

The Game Changer: In-Office CAD/CAM Systems

Some advanced CAD/CAM systems, like the Sirona CEREC, are designed to be used directly in the dental office. These systems are compact enough to fit into the practice, eliminating the need to send physical or digital impressions to an outside lab. The Sirona CEREC system, for example, includes a milling unit that can fabricate zirconia restorations right in the office. Paired with a fast-sintering zirconia furnace, this system enables dentists to provide same-day crowns and bridges, significantly improving patient convenience and satisfaction.

Dental Lab Shop: CAD/CAM Blocks for Optimal Results

For dental practices utilizing in-office CAD/CAM systems, having a reliable source for high-quality CAD CAM blocks is essential. Dental Lab Shop offers a range of blocks specifically designed for compatibility with systems like Sirona CEREC. Their zirconia blocks come in a stunning array of 20 colors, including popular bleach shades, ensuring that dentists can achieve the perfect shade match for each patient.

Key Features of Dental Lab Shop’s CAD/CAM Blocks:

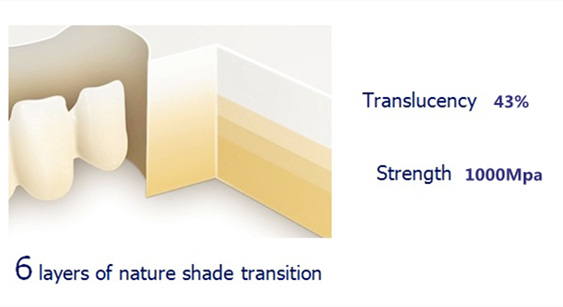

- 43% Transparency: This high level of transparency allows for the creation of restorations with a naturally lifelike appearance, blending seamlessly with the patient’s surrounding teeth.

- 1000 MPa Bending Strength: This exceptional strength ensures the longevity and durability of the restoration, even under the forces of chewing.

- Multilayer Technology: The multilayer feature is a true standout. It offers a highly aesthetic color gradient that transitions seamlessly from the cervical (gumline) area to the incisal (biting edge) area. This gradient mimics the natural translucency and color variation of teeth, resulting in restorations that are virtually indistinguishable from the real thing.

- Versatility: These blocks are suitable for fabricating a wide range of restorations, including crowns, bridges, and full-contour restorations.

The Bottom Line: CAD/CAM Blocks are Revolutionizing Dentistry

CAD/CAM blocks are more than just a material; they represent a fundamental shift in how dental restorations are created. They empower dentists to provide faster, more efficient, and more aesthetically pleasing treatments. With the ability to offer same-day crowns and bridges, dental practices can enhance patient satisfaction, improve workflow efficiency, and ultimately deliver better oral health outcomes. As technology continues to advance, we can expect CAD CAM blocks to play an even more prominent role in shaping the future of dentistry.