Mastering CAD/CAM Milling in the Dental Laboratory: A Guide for Dental Lab Students

As a dental laboratory technology student, you’re entering one of the most exciting and evolving fields in dentistry. Today’s labs blend traditional craftsmanship with cutting-edge digital technology—especially CAD/CAM milling units. While dry milling of zirconia prostheses is now a staple (fast, efficient, and low-maintenance), many students overlook the critical role of wet milling units. These machines handle precision work on materials that demand cooling to avoid cracks, overheating, or poor fit—such as titanium implants/abutments, crowns, and lithium disilicate (e.g., e.max) restorations.

Understanding both dry and wet milling is essential for producing high-quality, 100% fit prostheses that satisfy dentists and patients. A great dental lab technician isn’t born—they’re trained through rigorous courses, hands-on practice, and mastery of equipment.

What Is a Dental Laboratory Technician?

Dental lab technologists design, fabricate, and repair prosthetic appliances based on a dentist’s prescription. The role combines:

- Art (aesthetic design)

- Science (materials knowledge)

- Technology (CAD/CAM, milling, sintering)

- Engineering (precision fit)

- Business (lab management, communication)

Programs cover fixed prosthodontics (crowns/bridges), removable (dentures/partials), orthodontics, implants, dental anatomy, occlusion, chemistry/materials, infection control, ethics, and general education. Certification (e.g., Recognized Graduate or CDT exams) validates your skills.

Why Professional Training Is Essential

Achieving “100% fitness” for the patient means zero remakes, perfect margins, and ideal occlusion. This level of precision requires:

- Deep knowledge of materials properties

- Ability to read/interpret prescriptions

- Troubleshooting fabrication errors

- Safe handling of equipment

- Effective dentist communication

Without structured training, daily routines become guesswork. Formal programs build these foundations so you can transition smoothly into commercial labs, hospitals, dental schools, or private milling centers.

The Rise of CAD/CAM Milling in Modern Labs

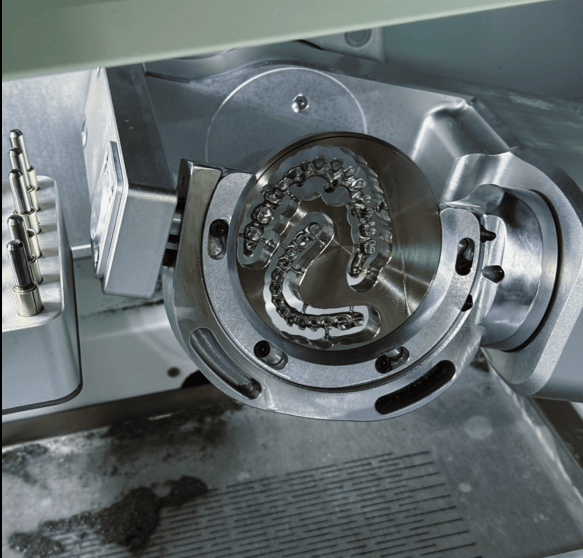

CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) has transformed dental labs. You design digitally (CAD), then mill the restoration (CAM) with incredible accuracy.

Dry Milling (The Popular Choice for Zirconia)

- No coolant needed

- Fast and clean

- Ideal for pre-sintered zirconia, PMMA, wax

- Low maintenance, high speed

Wet Milling: The Precision Powerhouse (Often Overlooked) Wet milling uses a continuous coolant (usually water + additive) to reduce heat and friction. This protects brittle or heat-sensitive materials and delivers superior surface finish, sharper margins, and longer tool life.

Key applications include:

- Titanium — for custom abutments, bars, implant frameworks (requires wet milling to prevent overheating and achieve smooth, biocompatible surfaces).

- Lithium disilicate (e.g., IPS e.max) — glass-ceramic crowns, veneers, inlays/onlays (wet milling prevents microcracks and ensures esthetic polish).

- Other: Hybrid ceramics, composites, some pre-mill abutments.

Many modern 5-axis wet mills handle titanium abutments, lithium disilicate crowns, and more in one unit—making them versatile for full-service labs.

Essential Dental Lab Equipment You Must Master

Your daily success depends on understanding and operating key tools safely and efficiently:

- Dental furnace/porcelain oven — for ceramic layering and sintering; learn temperature curves to avoid cracks or color issues.

- Pindex machine & dowel pins — for precise model/die production; know pin sizes, plate types, and proper application for removable cases.

- Dust vacuum/extraction systems — install under benches to maintain a clean, safe workspace (health regulations!).

- CAD/CAM systems — scanners, design software, milling units (dry & wet), sintering ovens.

- Others: Articulators, waxers, vacuum mixers, casting machines.

Where Do Dental Lab Graduates Work?

- Commercial dental labs

- Hospitals or dental schools

- Private dental offices

- Dental supply companies (research, sales, or reps)

- Teaching roles in tech programs

- Owning private milling centers

Many successful owners started by mastering equipment specs, CAD/CAM workflows, and dentist communication—skills you build in training.

Course Goals: What You Should Achieve as a Graduate

Upon completion, you should be able to:

- Follow accepted fabrication practices

- Understand dental materials properties

- Read technical manuals and troubleshoot errors

- Apply anatomical/physiological knowledge

- Interpret and fulfill prescriptions accurately

- Use effective communication for dentist collaboration

- Practice safety and infection control

- Apply math for ratios/measurements

- Stay current (attend exhibitions for new tech and free courses!)

- Prepare for certification exams (e.g., CDT)

- Uphold ethics and professional scope

Final Advice for Aspiring Techs

Embrace both dry and wet milling—don’t limit yourself to zirconia alone. Wet units open doors to high-value work like titanium abutments and premium lithium disilicate restorations.

Invest in training now: hands-on practice, courses, exhibitions, and certification. The payoff? You’ll produce flawless cases, earn respect from dentists, and build a rewarding career—whether in a big lab or your own milling center.

Your future patients (and dentists) are counting on that perfect fit. Master the tools, and the rest follows. Keep milling forward!